Plastics

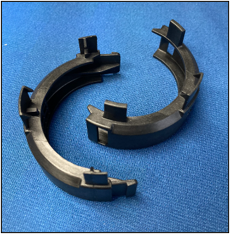

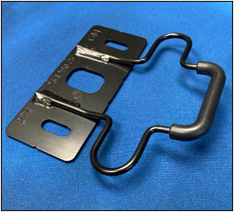

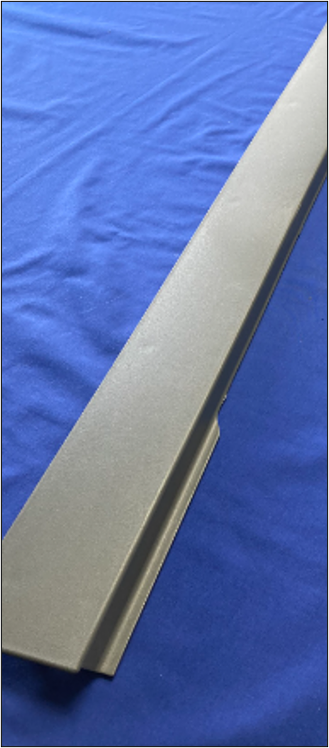

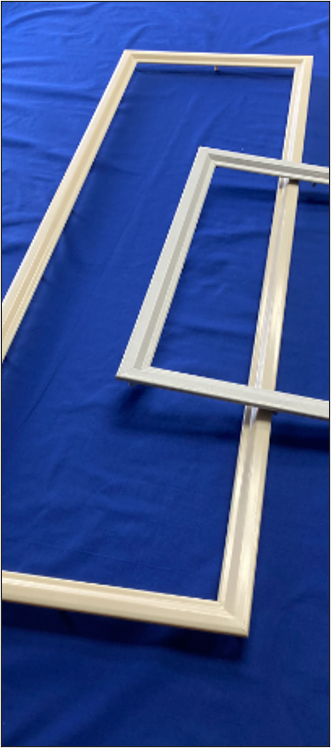

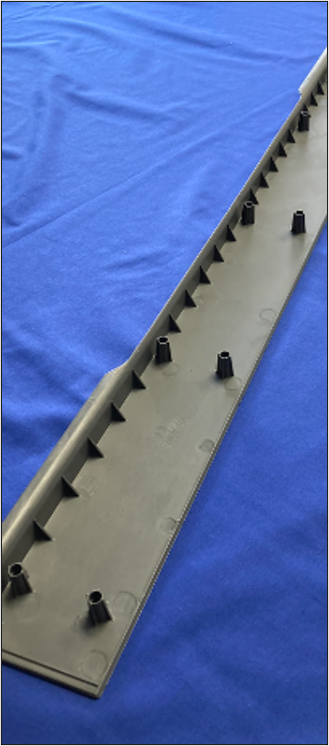

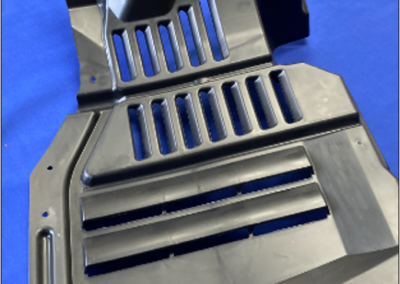

Plastic Injection Molded Parts for Precision Applications

In-house mold expertise provides scalable production and turnkey fulfillment

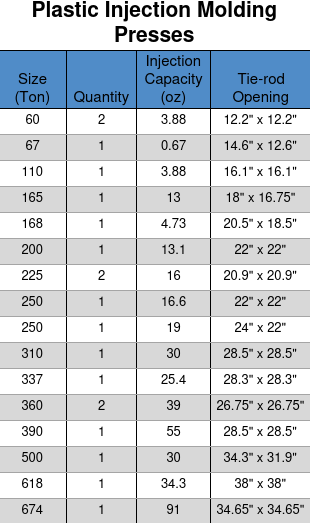

At Reed City Group, our manufacturing capabilities span from 45-ton to 674-ton plastic injection molding machines, plus the full-scale capability to take you from tooling to final assembly under one roof. Our experienced team of 215 employees includes two design teams, expert journeyman mold makers, process engineers, sales engineers, program managers, and skilled manufacturing workers. You can count on our over 60-year history of precision, quality, and competitive solutions.

- Production Molding, Low to High Volumes

- Prototype and Small Batch Molding

- Process Design and Manufacturing Automation Solutions

- Assembly and Secondary Operations

- Specialty Molding (Insert and Over Molding)

- Quality Assurance, Inspection and Testing

- Fulfillment, JIT Delivery and VMI

- Small and Large Mold Building Capability

- Mold Engineering Changes and Maintenance

Part Inspection, Assembly, Testing, and Fulfillment

We don’t stop at mold parts with every aspect of the manufacturing process under our roof. We also provide turnkey part inspection, assembly, and shipping.

Joining our skilled tradesmen, who ensure the unerring quality of plastic injection molds and parts, is our plastic injection molding fulfillment team. Skilled part experts guide the inspection, assembly, and quality control process. Alongside these parts experts, and our experienced shipping and logistics experts, our program managers guide the packaging and fulfillment process, creating turnkey injection molded part production.

Automated Material Handling & Specialty Equipment:

- 2 Chillers

- 10 Dryers

- 3 Grinders

- 2 Tippers

- 1 Hot Plate Welder

- 13 Star Automation Robots/Pickers

- 2 Assembly / Inspection Stations

- 1 Motan Vacuum Loading Systems: 6 Stations

- 1 4-Zone Valve Gate Controllers

- 4 Overhead Crane Hoists (10-30 Tons)

Design-to-Assembly Capabilities Under One Roof

At Reed City Group, our manufacturing capabilities span from 45-ton to 674-ton injection molding machines. We can control the manufacturing process from design to molding, bringing each step of the plastic injection molding process under one roof. Production capabilities in our 80,000-square-foot facility are virtually limitless. Our team has manufactured parts of all sizes, performance requirements, and complexities.

With a robust portfolio of high-performance automotive part manufacturing, our facility’s scalability is perfect for long and short runs in automotive, consumer products, and many other industries.